GB-880PA2FC2T-R

- Product Description

- Product Specifications

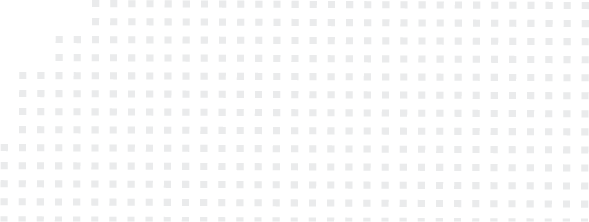

- The feeding system

The equipment is Individual of feeding system. To avoid working piece separated easily. It assemble a lot of top press rollers for strengthen feeding power. - Top pressure rollers

Sanding heads of this machine have automatic compensation device and automatic feed back functions. To avoid the machine bevel the end of working piece. - The head is industrial cutting head. It has equipped the floating and copy function, driven power 7.5HP (optional 10HP) and the angle of the head can fine-tuned the vertical angle.

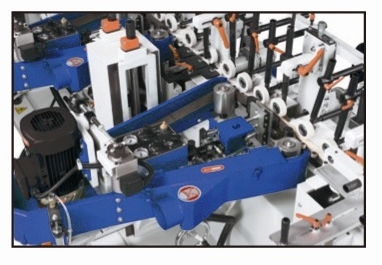

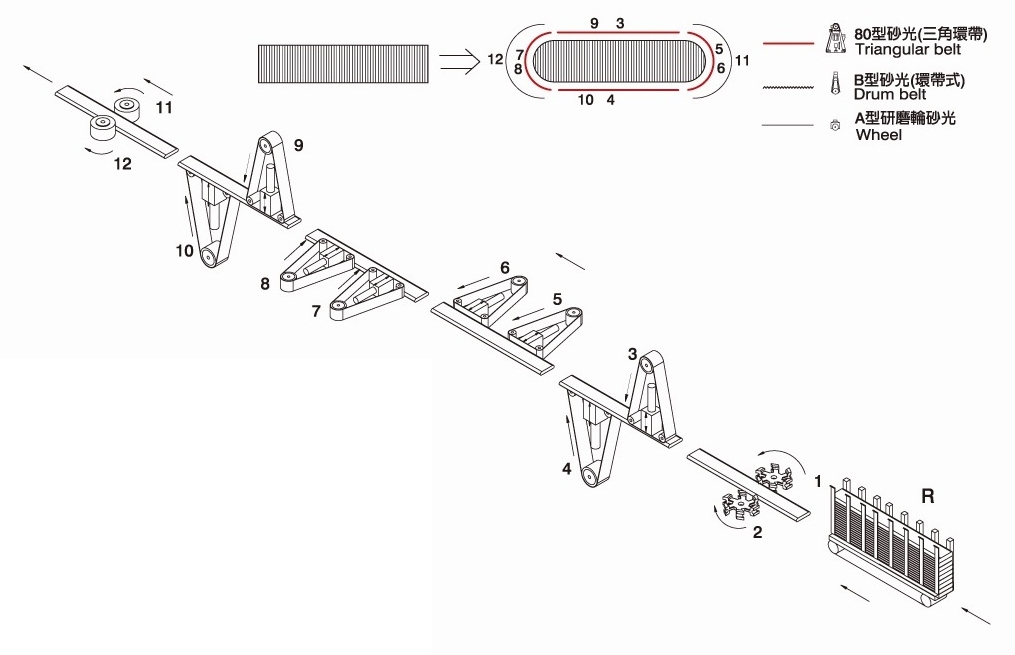

- The triangular belt head (Down/Up)

The head is the Industrial triangular belt head (80). The abrasive belt configure with oscillating device and air jet clean device. (Down to side ) The head tilts 20 up to -90 degree.(UP to side) The head tilts -20 up to 90 degree. - The head is Industrial triangular belt head (80). Manual control panel is easy operation. The speed of abrasive belt and the tension of abrasive, they are design for easy adjustment.

- The industrial wheel head (A) with auto compensation device, the range of angle adjustment is 110 degree.

- The feeding system

The equipment is Individual of feeding system. To avoid working piece separated easily. It assemble a lot of top press rollers for strengthen feeding power. - The feeding piece against with a Data plane for sanding accuracy.

- The machine frame is welded from rigid thick gauge steel plate, ruggedly constructed and precision machined for superior sanding accuracy and long service life.

- The feeding system

The structure configures with top pressure belt and feed pad to strengthen feed capability. The press base adjusts using electrical controller.

Raw material. WPC

WPC It has better stability than wood, so it does not require special maintenance and has a long service life.

Up to 25 to 30 years.

After polishing machine the plastic material (WPC)

The surface is more like the color of the original wood, with texture and a more even surface.

| MODEL | GB-880PA2FC2T-R |

| The. work-piece width | 5-150 mm |

| The. work-piece height | 5-100 mm |

| Min. work-piece length | 550 mm |

| Molding head | 2 set |

| Spindle motor | 7.5 HP |

| Speed | 6000-7800 R.P.M |

| (80) Sanding belt | 8 sets |

| (80) Sanding belt unit can adjustment height and traverse and tilting | |

| Sanding belt | 3" x 98" |

| Motor drive of sanding belt | 2 HP x 8 sets |

| Sanding belt equipped with automatic Air jet blow dust device | |

| (P) Sanding belt with oscillation device | |

| Oscillation device motor | 25W x 1/36 |

| Sanding belt speed control | By variable speed of frequency inverter |

| (A) Sanding wheel | 2 sets |

| (A) Sanding wheel unit can adjustment height and traverse and tilting | |

| Motor drive of sanding wheel | 2 HP x 2 sets |

|

(F) Sanding wheel equipped with automatic compensation device |

|

| Automatic compensation device motor | 25W x 1/180 |

| Sanding wheel speed control | By variable speed of frequency inverter |

| Feed motor | (1/4 HP x 1/25) |

| Feed speed | 3-38 m/min By variable speed of frequency inverter |

| Feed equipment | |

| Length of feeding belt conveyor | 1M |

| Width of belt conveyor | 150 mm |

| Motor drive | 1/2 HP |

| Speed | Inverter (Variable) |

Inquiry

Inquiry